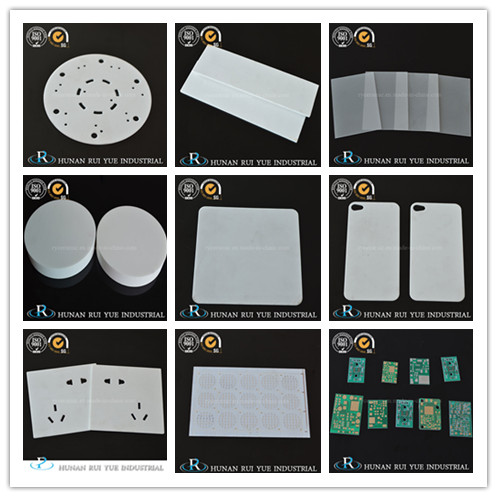

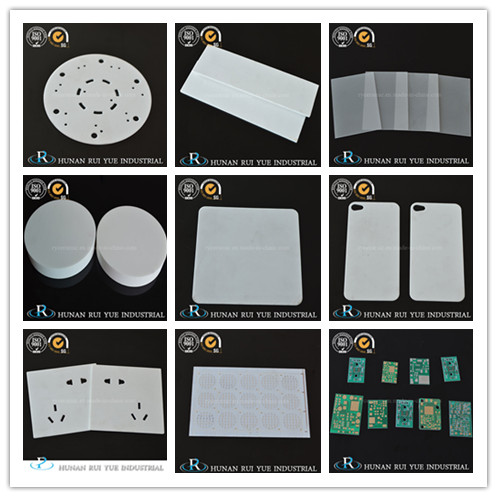

Product Description

Model NO.: RY-CZ-0010

Standard: GB

Production Type: Mass Production

Material:

Zirconia ceramic Rycolor: White, Ivory, Pink

Product: Metallized Ceramic

Raw Material: 60-99.7%

Alumina Ceramic Trademark: RY

Specification: According to customer request

HS Code: 6909190000

Application: Auto and Motorcycle Accessory, Machinery Accessory

Surface Treatment: Polishing

Machining Method: CNC Machining

Max Working Temperature: 1600c

Special: Metallized Ceramics Insulator

Name: Machine

Alumina Ceramic Substrate Item: Alumina Ceramics Insulator

Transport Package: Carton

Origin: China

Zirconia Toughened

Alumina ceramic with High Temperature Resistance

Zirconia Toughened Alumina(ZTA or AZ) products have these advantages: good tenacity, high temperature resistance, high strength and wear-resistant. The company's practical experience and advanced molding technology, stable quality,1800 ultra-high temperature kiln firing the school. Undertake user requirements can be zirconia toughened zirconia series of product development and production.

Polishing zirconia ceramic washer insulating parts

1.High strength, high fracture toughness, wear resistant, high hardness, corrosion reistance, ultra smooth surface.

easy clean, reduce the intermal friction between the beads and improve the material flow efficiency.

2. Good spherical degree

3. Lower costs for its long using life.

Application:

They are made of high purity and super-fine raw material with the application of the most advanced technology in the world. It can be mainly used to grind and disperse super-fine powder.

Specification

Zirconia ceramic are applicated as shaft bearing ,plunger,sealing matetial and knife, with high density, hardess ,bending strength and breaking tenacity. |

Zirconia ceramics properties |

Density |

g/cm3 |

6.0 |

Water absorption |

% |

<0.05 |

Firing temperature |

°C |

1550 |

Hardess |

HV |

1350 |

Bending strength |

MPa |

950 |

Compression strength |

Mpa |

25000 |

Breaking tenacity |

Mpa·m1/2 |

6-8 |

Thermal expansion coefficient |

/°C |

9.5x10-6 |

3:Workshop Photo:

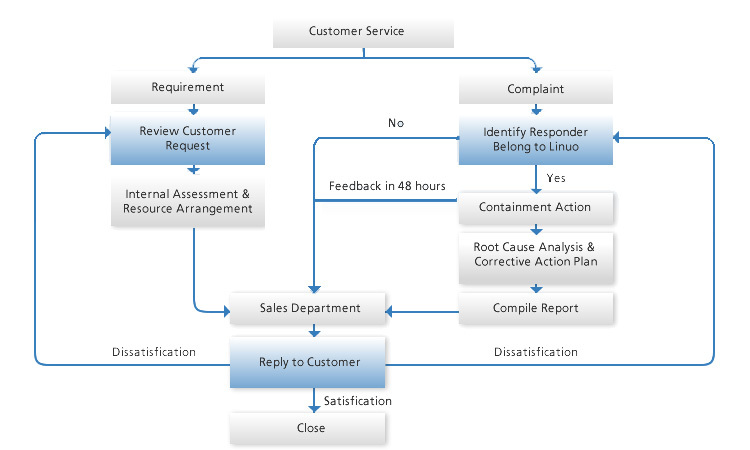

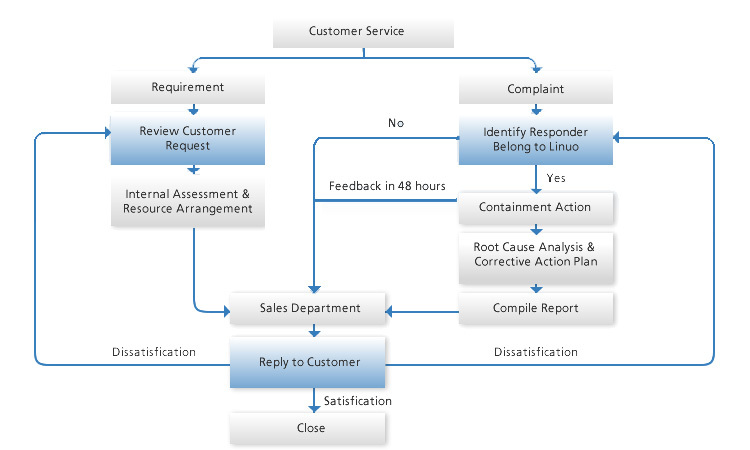

4:Our Service:

5:What can we do for you?

1. Sample is available.

2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll get.

8. Necessary Certificates can be supplied.

9:Why To Choose Us

1. Low MOQ:

It won't occupy too much of your money to help you to test the market you're going to enter.

2. R & D Center and Factory:

We have our own R & D center and factory, so we can supply you products at competitive price.

3. Good Service :

We treat clients as friends.

4. Good Quality :

We import top quality accessories to manufacture our products, we have confident we can offer you the best quality.

5. After-sales service:

One year's guarantee. Wearing accessories comes with the products to help you to reduce the repair bill.

Contact us if you need more details on

Zirconia Ceramic Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Zirconia Metallization Plate、

Metallized Ceramic Substrate. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Zirconia Ceramic Spare Parts