| Unit Price: | 0.92 USD |

|---|

| Min. Order: | 1 Piece/Pieces |

|---|

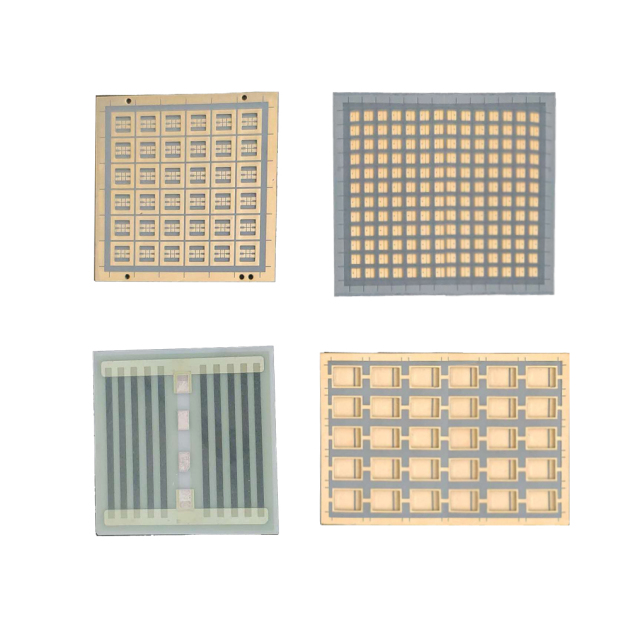

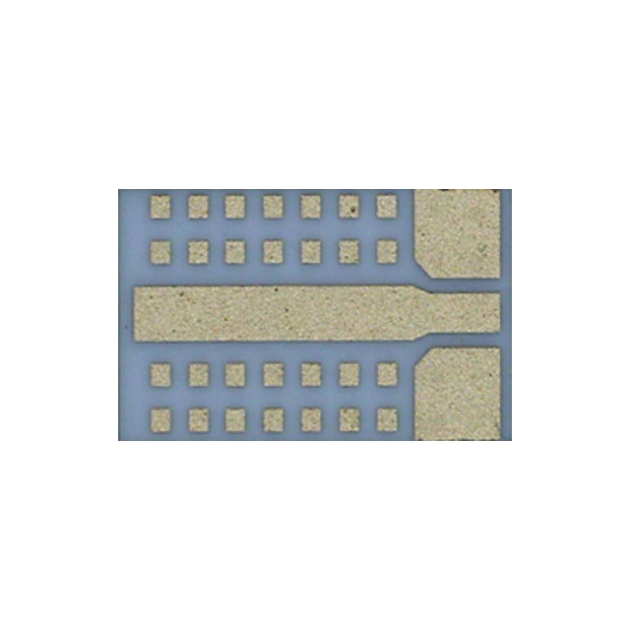

Product Description

How are ceramic PCB made?

Ceramic substrate printed board, due to its heat dissipation performance, current-carrying capacity, insulation, thermal expansion coefficient, etc., is much better than ordinary glass fiber PCB board, so it is widely used in high-power power electronic modules, aerospace, military electronics and other products on.

With ordinary PCB, the copper foil and the substrate are bonded together with an adhesive. Ceramic PCB is in a high temperature environment, the copper foil and the ceramic substrate are joined together by bonding, and the bonding force is strong. The copper foil Will not fall off, high reliability, stable performance under high temperature and high humidity environment.

2. The main material of the ceramic substrate

Alumina (Al2O3)

Alumina is the most commonly used PCB substrate material in ceramic substrates, because compared to most other oxide ceramics in terms of mechanical, thermal, and electrical properties, it has high strength and chemical stability, and has abundant sources of raw materials, making it suitable for a variety of Technical manufacturing and different shapes. According to the percentage of alumina (Al2O3), it can be divided into: 75 porcelain, 96 porcelain, and 99.5 porcelain. The content of alumina is different, its electrical properties are hardly affected, but its mechanical properties and thermal conductivity vary greatly. PCB substrates with low purity have more glass phases and large surface roughness. The higher the purity of the PCB substrate, the smoother, denser, and the lower the dielectric loss, but the higher the price.

Beryllium Oxide (BeO)

It has a higher thermal conductivity than metal aluminum, and is used in applications requiring high thermal conductivity. The temperature drops rapidly after the temperature exceeds 300°C, but its toxicity limits its own development.

Aluminum Nitride (AlN)

Aluminum nitride ceramics are ceramics with aluminum nitride powder as the main crystal phase. Compared with Alumina Ceramic Substrate, it has higher insulation resistance, higher insulation withstand voltage and lower dielectric constant. Its thermal conductivity is 7-10 times that of Al2O3, and its coefficient of thermal expansion (CTE) is approximately matched to that of silicon wafers, which is essential for high-power semiconductor chips. In the production process, the thermal conductivity of AlN is greatly affected by the residual oxygen impurity content, and reducing the oxygen content can significantly increase the thermal conductivity. At present, the thermal conductivity of the current production level of 170W/(m·K) is no longer a problem.

Based on the above reasons, it can be known that due to its superior comprehensive performance, alumina ceramics is still in a leading position in the fields of microelectronics PCBA, heavy copper board power electronics, high frequency mixing pressure plate, high frequency mixing pressure plate power modules and other fields.

Contact us if you need more details on Order Ceramic PCB & Substrates Online. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic PCB PCBgogo、Ceramic Printed Circuit Boards. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Rigid-Flex Board > Flame Resistant PCB