Product Description

Model NO.: Ry-CT-0015

Feature: Long Time Materials, Instant Materials, High Temperature

Shape: Pipe

Surface Treatment: Polish

Item:

Alumina Pipe Lined in Steel Pipe

Denisty: 3.6-3.9

Product: Corundum Ceramic Tubes

Transport Package: Wooden Case or Wooden Pallet

Origin: China

Refractoriness (℃): 1580< Refractoriness< 1770

Type: Refractory Material

Material: Alumina Cement

Firing Temperature: 1550~1680degree Centigrade

Raw Material: 99-99.7%

Alumina Ceramic Color: White, Pink, Light Yellow

Trademark: RY

Specification: according customer request

HS Code: 690919000

high working temperature

Alumina Ceramic Tube for casting

1:

Alumina ceramic Tubes Introduction:

95% AL2O3 ceramic thermocouple protection tube:

Volume density: 3.7g/cm³

Bending strength: 364MPa

Expansion coefficient (X10-6/ºC) (25-800ºC) : 7.6

Thermal conductivity: 20W/(m.R)

Insulation strength: 11kV/mm

Long term service temperature: 1480°C

Water absorption: <0.2%

99% AL2O3 ceramic thermocouple protection tube:

Volume density: 3.9g/cm³

Bending strength: 450MPa

Expansion coefficient (X10-6/ºC) (25-800ºC): 8

Thermal conductivity: 38W/(m.R)

Insulation strength: 12kV/mm

Long term service temperature: 1600ºC

Water absorption: <0.1-0.2%

2:Ceramic tube pipe advantages

High hardness

Superior abrasion

Corrosion and chemical resistance

Light weight

Low maintenance cost: Super wear-resistance reduce the maintenance frequency and also the maintenance cost.

Good fluidity : Smooth surface ensure the free flow of material without blocking

Fuse tube

Steel wear-resisting lining

Acid and alkali resistance, high temperature resistance ceramic tube

It is widely used in such industry as power, mining, metallurgy and coal

3:Specifications:

| Dimension | Outer dia. mm | Inner dia.mm | Length mm | Remark |

| Item |

| Thermocouple protection tube | 7-120 | 1-110 | 10-2000 | If you need others,we can customize for you. |

| Insulated tube | Single hole | 2-120 | 1-110 | 10-2000 |

| (inner core) | Double holes | 1-10 | 0.4-2 | 10-2000 |

| | Four holes | 2-10 | 0.5-2 | 10-2000 |

4:Property of material:

| AL2O3% Composition | Density | Flexural Strength | Thermal Conductivity | Dielectric Strength | Working Temp. |

| (g/cm3) | (MPa) | [w/(m.R)] | (KV/mm) |

| 60 | 3 | 205 | 16 | 10 | 1000°C |

| 75 | 3.1 | 280 | 17 | 10 | 1250°C |

| 80 | 3.3 | 215.7 | 17 | 10 | 1290°C |

| 85 | 3.4 | 230 | 17 | 10 | 1350°C |

| 92 | 3.6 | 312 | 18 | 10 | 1390°C |

| 95 | 3.7 | 304 | 20 | 10 | 1480°C |

| 99 | 3.81 | 340 | 34 | 10 | 1600°C |

| 99.7 | 3.85 | 370 | 35 | 10 | 1700°C |

5:Other information:

| Feature | Application | Main usage |

| 1.Great mechanical strength | Electric appliance industry Automotive industry | 1.Heat treatment furnace and toughened furnace |

| 2.High softening temperature |

| 3.Good resistance to thermal impact |

| 4.Small thermal expansion coefficient | Mechanical industry Engineer industry | 2.Inner liner tube and heating tube in electric furnace |

| 5.Good chill and abrupt heat properties |

| 6. Resistance to acid and alkali corrosion |

6:Workshop Photo:

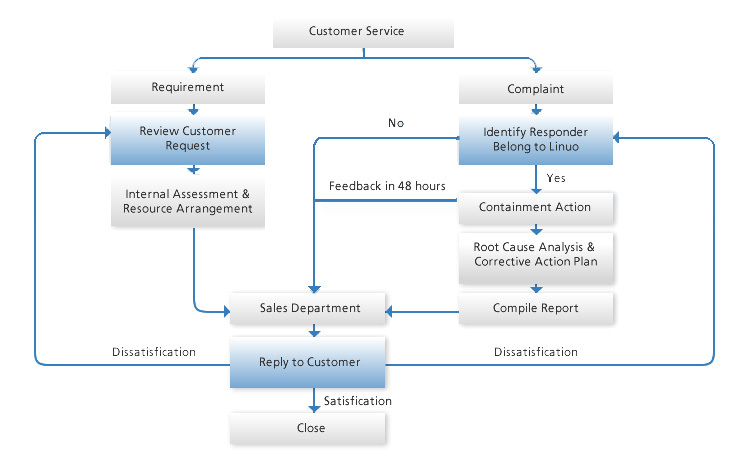

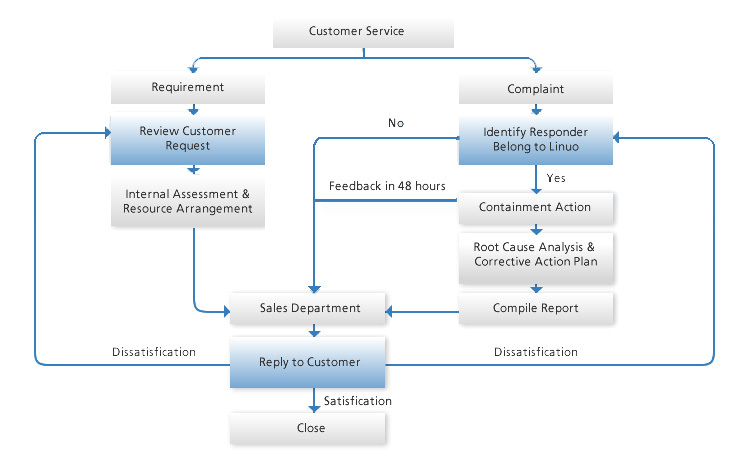

7:Our Service:

8:What can we do for you?

1. Sample is available.

2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll get.

8. Necessary Certificates can be supplied.

9:Why To Choose Us

1. Low MOQ:

It won't occupy too much of your money to help you to test the market you're going to enter.

2. R & D Center and Factory:

We have our own R & D center and factory, so we can supply you products at competitive price.

3. Good Service :

We treat clients as friends.

4. Good Quality :

We import top quality accessories to manufacture our products, we have confident we can offer you the best quality.

5. After-sales service:

One year's guarantee. Wearing accessories comes with the products to help you to reduce the repair bill.

Contact us if you need more details on Aluminium Oxide Ceramic Tube. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 99% Alumina Ceramic Tube、Ceramic Tube. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Alumina Ceramic Products > Alumina Ceramic Tube/Rod