Product Description

Model NO.: RY-CP-0010 Feature: Long Time Materials Shape: Custom-Made Max Working Temperature: 1600c Special: Rectangular, Boat, Cylindrical Name: Machine

Alumina Ceramic Part Item: Alumina Ceramics Part Specification: According to customer request HS Code: 6909190000 Refractoriness (℃): 1580< Refractoriness< 1770 Type: Heat-Resistant Material Material: Alumina Cement Thermal Shock Resistance: 180-220t Product:

Alumina Parts Raw Material: 60-99.7%

Alumina ceramic Trademark: RY Origin: China High Purity Alumina

Ceramic Part Insulator Insulator Ceramic part Physical properties:

high insulation ,breakdown resistance , high temperature resistance, abrasion resistance, high strength (three meters altitude fall not broken)

Fireproof rating: America military standard MIL-F-51058 (the highest level)

Typical application: strong current and voltage, high temperature parts, IC MOS pipe, IGBT power pipe thermal insulation

Certification: natural organic matter, the EU's exemption products, without certification materials

Thermal conductivity: withstand voltage and temperature, below 1600 degrees high heatconduction voltage and high frequency for ideal equipment. Features: 1) A variety of specifications available. 2) Satisfy various technical request 3) Lower medium spoilage 4) Good insulation performance and high temperature resistance 5) High mechanical strength 6) High pressure 7) Good wear resistance Data Sheet :

| Material | 85 Al2o3 | 90 Al2o3 | 95 Al2o3 | 99 Al2o3 |

| Al2o3 | 85% | 90% | 93% | 99.30% |

| Fe2o3 | ≤ 1.0 | ≤ 0.5 | ≤ 0.5 | ≤ 0.3 |

| Desnsity: g / cm3 | 3.4 | 3.5 | 3.6 | 3.85 |

| Vickers Hardness | ≥ 8.6 | ≥ 8.8 | 9 | 9 |

| Water Absorption:% | ≤ 0.2 | ≤ 0.1 | ≤ 0.085 | ≤ 0.01 |

| Refractoriness:°C | 1580 °C | 1600 °C | 1650 °C | 1800°C |

| Flexural Strength:Mpa | 180 | 200 | 240 | 280 |

| Wear Rate( at room temperature, erosion, 100 grinding)% | ≤ 3 | ≤ 2.5 | ≤ 1 | ≤ 0.5 |

2:Application: Electronical Vacuum decices, Cruibles, Insulation plates, Capacitors, Spaceflights, Traffic, Weave, Petro Chemical, Mine, Pharmaceutical Engineering, Communication Engineering and Archtectural, etc

Alumina Ceramic Sheet is mainly used in high power equipment, IC MOS tube, IGBT patch type thermal conduction and insulation, high frequency power supply, communications, mechanical equipment, strong current, high voltage and high temperature of product parts need to heat conduction and insulation.

3:Workshop Photo:

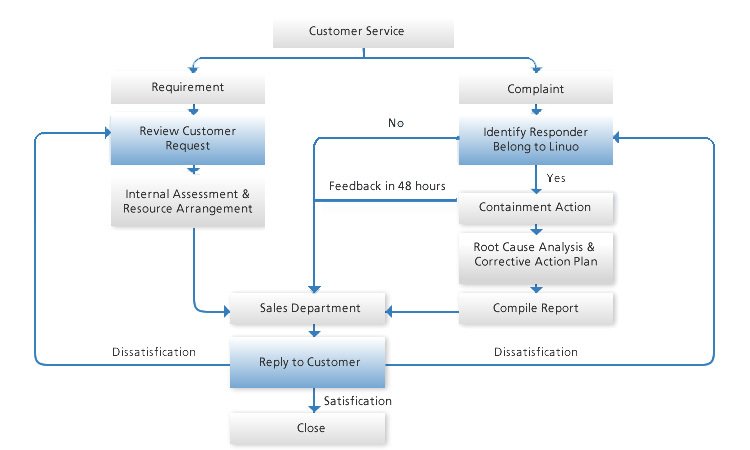

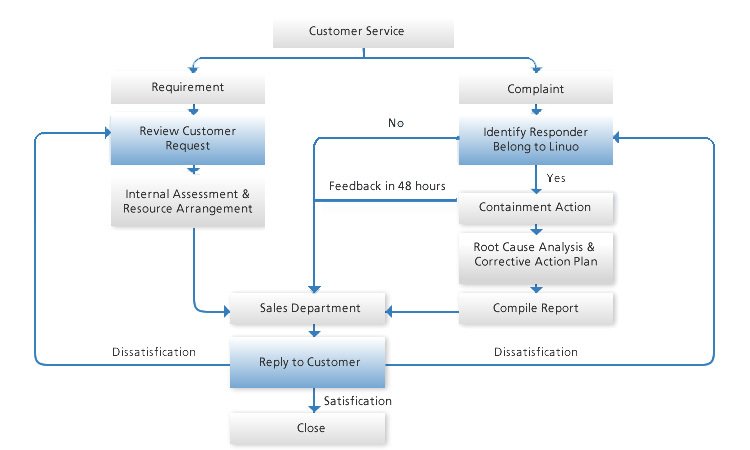

4:Our Service:

5:What can we do for you?

1. Sample is available. 2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy. 3. Inquiry replied within 24 hours. 4. Patented products. 5. OEM or ODM is available. 6. Some extra accessories can be supplied. 7.The larger quantity you order,the more competitive prices you'll get. 8. Necessary Certificates can be supplied. 9:Why To Choose Us 1. Low MOQ: It won't occupy too much of your money to help you to test the market you're going to enter. 2. R & D Center and Factory: We have our own R & D center and factory, so we can supply you products at competitive price. 3. Good Service : We treat clients as friends. 4. Good Quality : We import top quality accessories to manufacture our products, we have confident we can offer you the best quality. 5. After-sales service: One year's guarantee. Wearing accessories comes with the products to help you to reduce the repair bill.

Contact us if you need more details on Alumina Ceramic Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

99.5% Alumina Part、Ceramic Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Alumina Ceramic Products > Alumina Ceramic Spare Parts

3:Workshop Photo:

3:Workshop Photo: